Clamp, digital and multimeters are included in this category. Resistance tester; infrared scanner; portable test equipment, such as high potential tester; the main function of the instrument and test equipment is to help installers and maintenance personnel to ensure the reliability, efficiency and profitability of electrical systems and equipment.

Clamp, digital and multimeters are included in this category. Resistance testers; infrared scanners; portable test equipment, such as high-potential testers; and desktop devices.

The main function of instruments and test equipment is to help installers and maintenance personnel to ensure the reliability, efficiency and profitability of electrical systems and equipment. They are tools that allow measurements (rather than visual inspections) to determine the status of electrical components and systems. This type of equipment ranges from simple handheld devices to sophisticated laboratory instruments. However, all of these require a certain level of skill to use them correctly and analyze the results accurately.

Handheld meter

The most widely used instruments are handheld instruments, which usually include clamp meters and multimeters. The clamp meter is widely used because of its easy operation. Multimeters are also popular because they are easy to carry and can perform a wide variety of measurement ranges. These units have a large number of accessories available, so they can be used to measure light levels, temperature and other variables to further expand their use for electricians. Most of them can provide digital or analog readings, and the choice depends largely on the user’s personal preferences and accuracy requirements.

Both clamp meter and multimeter can be of average response or true effective value type. The true RMS unit responds to the effective heat generation of the AC waveform. The averager calculates the arithmetic average of the waveform. When the signal to be measured is close to a pure sine wave, an average response meter or a true effective value meter can be used with reasonable accuracy. However, if the waveform is distorted (for example, common in circuits that supply phase-to-neutral and phase-to-non-linear loads), true rms sensing devices are preferred because the readings will be more accurate。

Portable test equipment

Megaohmmeters, including special versions for determining the resistance of grounding systems, are also widely used. They can be shaken manually or battery powered, and have various levels of complexity.

Facts have proved that recording instruments are very helpful for long-term analysis of system parameters (such as current, voltage, electrical noise, waveform, etc.). Devices of this type range from relatively simple dot matrix printers to high-speed computer units.

As more and more nonlinear loads become the norm in today’s offices and factories, harmonic analyzers have become extremely important.

Thermal measuring instruments are also very popular as a means of detecting overheating of electrical system equipment. These instruments range from simple units (read directly on the meter scale) to highly complex instruments (heat maps (infrared photos) are available), which can accurately show the location of hot spots. Infrared sensing equipment is very suitable for finding loose connections, fuse clip corrosion, connector deterioration and other potential failure points that may heat up.

Larger portable test equipment includes high-current testers for checking the operation of power circuit breakers, relay testers for precise adjustment of protective relay settings, and high-potential testers for assessing continuity of medium voltage cables. Special equipment is used for power factor testing of large motors and transformers.

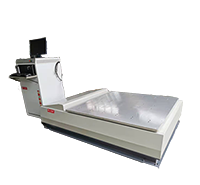

Bench test equipment

It is also possible to use laboratory-type equipment, for example, for analyzing oil samples of transformers. Gas chromatograph is used to detect trace traces of various materials (such as PCB). High-precision oscilloscopes, counters and other desktop equipment are also widely used in electrical installations and equipment testing.